High Pressure Grinding Rollers Market to Hit USD 2.2 Billion by 2035 — Growth Fueled by Energy Efficiency Demand

The High Pressure Grinding Rollers market will reach USD 2.2 billion by 2035, driven by mining efficiency and sustainability trends.

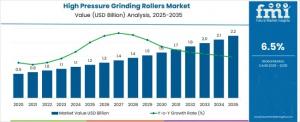

NEWARK, DE, UNITED STATES, November 10, 2025 /EINPresswire.com/ -- The global High Pressure Grinding Rollers market is set to experience significant growth, expanding from USD 1.2 billion in 2025 to USD 2.2 billion by 2035, representing a compound annual growth rate (CAGR) of 6.5%. The surge in demand for energy-efficient and sustainable grinding technologies across the mining and cement sectors continues to drive this momentum. As industries transition toward lower-carbon operations, HPGR systems have become a cornerstone technology for optimizing resource use and minimizing operational costs.

Market Overview and Growth Dynamics

The market’s expansion trajectory reflects a growing shift toward energy-conscious comminution technologies. From USD 0.9 billion in 2024, the HPGR market steadily rises to USD 1.0 billion by 2026, gaining traction with the adoption of advanced grinding circuits designed to reduce power consumption. By 2030, the market value is expected to cross USD 1.4 billion, marking a new era of efficiency-focused processing systems. The adoption curve steepens after 2032, culminating in the USD 2.2 billion milestone by 2035.

According to market intelligence, this growth is propelled by rising investments in modern ore processing plants and cement grinding systems, where HPGRs replace conventional mills due to their superior energy performance, reduced maintenance, and improved mineral liberation efficiency.

Leading Segments Driving Market Growth

The tinplate substrate segment dominates the HPGR market, projected to hold 41.2% of the total revenue share in 2025. Tinplate’s exceptional strength-to-weight ratio, corrosion resistance, and ability to endure extreme mechanical pressures make it a preferred choice for high-load grinding systems. Its recyclability and compatibility with sustainability standards further solidify its industrial adoption.

In terms of coating types, the organic coatings segment captures 33.2% of market share. These coatings are increasingly sought after for their ability to extend component life, resist corrosion, and minimize downtime in demanding grinding environments. Advances in polymer chemistry and surface engineering have enhanced coating performance, supporting longer maintenance intervals and higher throughput in HPGR operations.

Meanwhile, the two-piece can coating process leads the market with 55.9% of the revenue share in 2025. Known for its uniformity and structural integrity, this segment benefits from increased automation, reduced material waste, and improved mechanical strength — all critical factors for achieving consistent performance under high-pressure operations.

Regional Insights: Global Growth Accelerators

The Asia-Pacific region dominates the HPGR landscape, driven by large-scale mining and mineral processing activities in China and India.

- China leads with a projected CAGR of 8.8% (2025–2035), propelled by massive expansion in the cement and metals sector. The country’s drive for modernization and energy optimization in mining operations has accelerated HPGR adoption nationwide.

- India follows closely with an 8.1% CAGR, fueled by infrastructure growth and the cement industry’s ongoing transition to energy-efficient grinding technologies.

- Europe, led by France (6.8%) and Germany (7.5%), remains a mature market focusing on process optimization and eco-friendly production standards.

- North America, particularly the United States (5.5% CAGR), is witnessing a steady rise in HPGR installations as industries seek lower energy costs and sustainable manufacturing solutions.

Technological Advancements and Market Trends

The future of HPGR technology lies in smart digital integration and materials innovation. Manufacturers are incorporating IoT sensors, AI-based control systems, and predictive maintenance algorithms to enhance equipment reliability and performance monitoring.

Material science innovations, such as tungsten carbide studs and wear-resistant alloy coatings, are extending the operational life of HPGR components. These enhancements not only reduce unplanned downtime but also significantly cut lifecycle costs.

Moreover, the shift toward modular HPGR designs enables easier integration into existing processing plants, offering scalability for operators aiming to expand production without major infrastructure overhauls.

Explore the full market insights and future trends—read the complete Market Report today! https://www.futuremarketinsights.com/reports/sample/rep-gb-24139

Buy Now Report Here: https://www.futuremarketinsights.com/checkout/24139

Key Market Drivers

- Rising Demand for Energy-Efficient Solutions: HPGRs consume up to 20–50% less energy compared to traditional milling systems, making them a preferred option in regions with high power costs.

- Sustainability and Cost Optimization: Growing environmental regulations are pushing industries to adopt low-emission, high-efficiency grinding technologies, aligning with global sustainability targets.

- Process Efficiency and Improved Recovery Rates: HPGRs offer superior metal liberation and improved downstream recovery, enhancing yield from lower-grade ores — a crucial advantage in modern mining operations.

Challenges and Opportunities

Despite its advantages, the HPGR market faces challenges such as high upfront capital investment and specialized maintenance requirements. However, innovations in component design, wear-resistant materials, and automated maintenance systems are mitigating these concerns.

Emerging opportunities lie in digital optimization, AI-enabled process control, and customized HPGR solutions for niche applications such as lithium processing and fine particle production. These innovations are expected to unlock new value streams and broaden market penetration.

Competitive Landscape

The HPGR industry is dominated by key players focusing on technology-driven solutions and process optimization. Major participants include:

CITIC Heavy Industries Co. Ltd., FLSmidth, KHD Humboldt Wedag International AG, Cast Steel Products, The Weir Group PLC, Thyssenkrupp Koppern Group, Outotec Oyj (Metso Outotec), and TAKRAF GmbH (Tenova Core Inc.).

These companies are leveraging advanced engineering, material technology, and digital platforms to enhance equipment lifespan, reduce energy consumption, and improve operational consistency across diverse industrial applications.

Outlook

As the mining and cement industries continue to emphasize sustainability, efficiency, and automation, the High Pressure Grinding Rollers market is positioned for robust growth through 2035. With evolving technologies, expanding industrialization in Asia, and global sustainability mandates, HPGR systems are set to redefine the future of energy-efficient material processing worldwide.

Related Reports:

Industrial Robots Market- https://www.futuremarketinsights.com/reports/industrial-robots-market

Glass Tempering System Market- https://www.futuremarketinsights.com/reports/glass-tempering-systems-market

Lamella Clarifier Market- https://www.futuremarketinsights.com/reports/lamella-clarifiers-market

Have a specific Requirements and Need Assistant on Report Pricing or Limited Budget please contact us - sales@futuremarketinsights.com

About Future Market Insights (FMI)

Future Market Insights, Inc. (FMI) is an ESOMAR-certified, ISO 9001:2015 market research and consulting organization, trusted by Fortune 500 clients and global enterprises. With operations in the U.S., UK, India, and Dubai, FMI provides data-backed insights and strategic intelligence across 30+ industries and 1200 markets worldwide.

Contact Us:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

Why FMI: https://www.futuremarketinsights.com/why-fmi

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Sudip Saha

Future Market Insights Inc.

+1 347-918-3531

email us here

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.